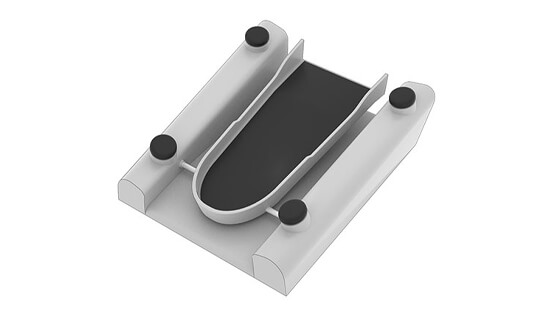

Foot control panel for the operating room

Corscience develops hardware, firmware and mechanics

Systems engineering is one of our core competences here at Corscience. This is where we offer everything from a single source: Hardware, firmware and mechanics development. We were once again able to demonstrate our expertise in systems engineering and mechanics to develop a new type of foot control panel for use in the operating room for a long-standing customer.

The foot control panel is integrated into an operating system and controls a safety-critical application. For this particular customer project, our expertise in the development of robust mechanics and a Bluetooth connection was particularly in demand.

Features

Among other things, the newly developed, customized foot control panel is characterized by

- mechanical robustness and reliability,

- a communication connection via both Bluetooth and cable,

- an intelligent energy supply concept via cable and battery,

- integrated class C software with the strictest safety standards and

- the highest IPX8 sealing class according to DIN EN 60529.

Interaction between electronics and mechanics

The foot control panel combines sophisticated electronics with robust mechanics. So this means it has several interfaces: Aside from the Bluetooth communication interface, CAN bus communication is integrated. The precise sensor technology ensures sensitive handling. User input is converted with a high degree of accuracy and error-free operation is guaranteed.

The housing is made from high-quality plastic. The design and customer requirements were implemented in a flexible way using rapid prototyping technology and were finally realized for series production with a high number of injection-moulded components.

Technical and project management skills

Our teams have a broad range of expertise so that they can implement our customer projects efficiently: They solve very complex problems, e.g. in the fields of injection moulding and sealing technology, and they reliably implement routine tasks such as the verification and testing of mechanical assemblies. The use of modern development tools such as PTC Creo for the mechanics and Pulsonix for the hardware development is a matter of course. For close, reliable cooperation, our customers can rely on our expertise in project management.

Numerous successful mechanics projects

When it comes to the field of mechanics development, we can rely on our many years of project experience. This, in particular, refers to the construction of defi housings and defi paddles, gesture-controlled lights in operating rooms, housings for pneumatically-operated cardiac support systems through to the construction of test stands for verification and assembly aids for production.

Corscience stands for hi-tech medical solutions that help people and save lives. We would be delighted to develop and produce an individual product for you.